Crane Types in PEB

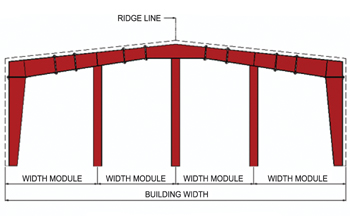

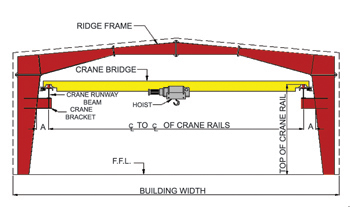

Crane types- We design the building to take the loads of the followings crane systems as per customer requirements.All pre-engineered steel buildings can be designed for crane operation provision as per operational need. There is various type of crane being used in industry for various purposes.For each type of crane there is suitable design criteria for peb design and structure can be adequately designed to meet the functional requirement and crane provider.

- EOT overhead crane with pendant or cabin operated.

- Overhung/under-slung crane system.

- Monorail crane or hoist system.

- Wall mounted crane.

- Jib crane.

Our Product suppliments

- Crane bracket

- Crane beams

- Lateral kicker angles

- Vertical bracing

- Rafter brackets

PEB METAL provides all necessary structure e.g. crane brackets, crane girders, end plate walkways, cage ladder for access ,Crane rails, Modular beam hoist and bridge etc. as per user requirement. For most economical and accurate building design, please advise your crane manufacturer’s contact details at time of request for quotation.

Top Running Crane

Underhung Crane

Jib Crane

Monorail Crane