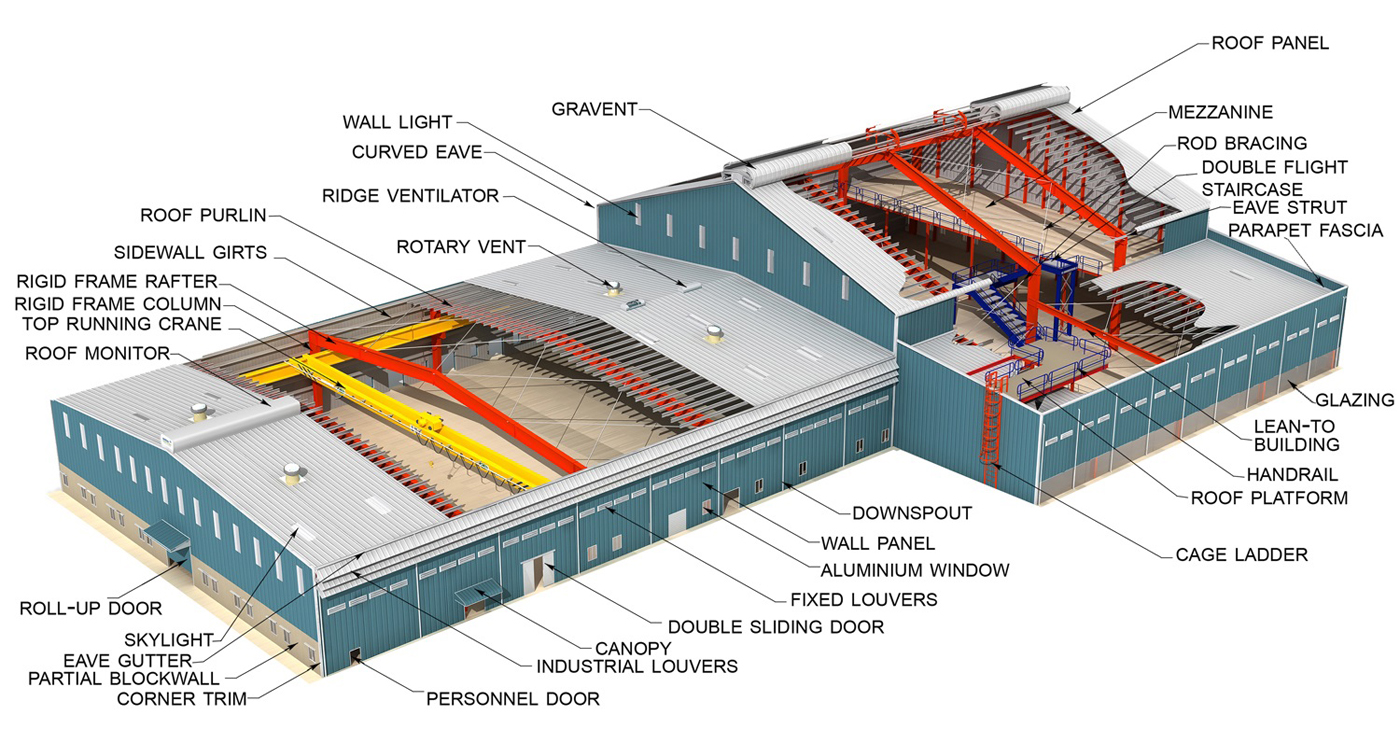

Building Panel AccessoriesUsed in PEB

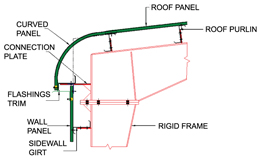

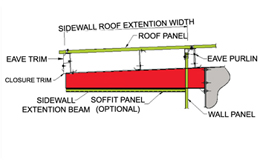

Trims, Gutters, Downspouts and Sundry Items

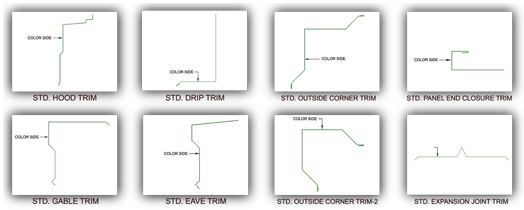

Standard Wall Trims

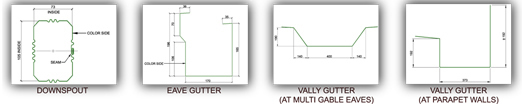

Building Panel Accesories – PEB Metal Provides Building Panel Accesories including corner trim, eave trim, gable trim, eave gutters and downspouts are Produced from the same material as the Wall and Roof Panels.

Valley gutters are made from 0.9mm thick G-90 galvanized steel.

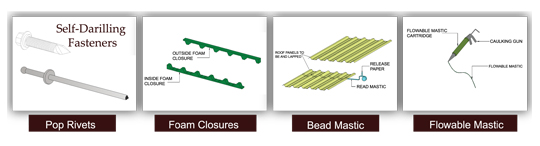

Panel sundry Items : PEB Metal uses Building Panel Accessories Such as selfdrilling carbon fasteners with AluZinc coated steel panels and stainless steel fasteners with Aluminum panels. Both have 5.5 mm diameters and 19mm diameter washers.

Building Panel Accessories